Introduction to 3D Printing

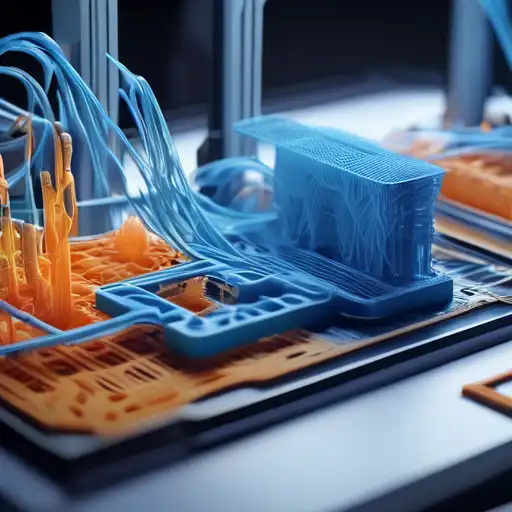

3D printing, also known as additive manufacturing, is a process of creating three-dimensional objects from a digital file. This innovative technology builds objects layer by layer, offering unparalleled flexibility in design and production. From prototyping to full-scale manufacturing, 3D printing is revolutionizing industries worldwide.

The Process Behind 3D Printing

The journey of 3D printing begins with a digital 3D model, which is sliced into thin layers by specialized software. The printer then follows these slices, depositing material layer upon layer until the object is fully formed. Materials range from plastics and metals to ceramics and even biological materials, opening up endless possibilities.

Applications of 3D Printing

3D printing is making waves across various sectors. In healthcare, it's used for creating prosthetics and even bioprinting tissues. The automotive and aerospace industries benefit from lightweight, complex parts that reduce weight and improve efficiency. Meanwhile, in the consumer sector, custom jewelry and home decor items are just a click away.

Healthcare Innovations

One of the most groundbreaking applications of 3D printing is in the medical field. Custom prosthetics and implants are now more accessible, and researchers are exploring the potential for printing organs, which could revolutionize transplants.

Industrial Manufacturing

3D printing allows for the creation of parts with complex geometries that were previously impossible or too costly to manufacture. This not only speeds up the production process but also significantly reduces waste, aligning with sustainable manufacturing practices.

The Future of 3D Printing

As technology advances, the potential for 3D printing continues to expand. Innovations in materials and printing techniques are paving the way for more sustainable and efficient manufacturing processes. The future may see 3D printers in every home, making personalized products a reality for everyone.

Sustainability and 3D Printing

3D printing promotes sustainability by minimizing waste through precise material usage and enabling the recycling of materials. This eco-friendly approach is crucial in today's effort to combat climate change and reduce industrial waste.

Challenges and Considerations

Despite its advantages, 3D printing faces challenges such as material limitations, high costs for industrial-grade printers, and intellectual property concerns. Addressing these issues is essential for the technology's widespread adoption.

Conclusion

3D printing is undeniably shaping the future of manufacturing, healthcare, and beyond. Its ability to turn digital designs into physical objects with precision and efficiency is unlocking new possibilities across industries. As we continue to explore and innovate, the layer-by-layer approach of 3D printing will play a pivotal role in creating a more sustainable and customized future.